Jonassen Industrial Projects Limited (JIPL) has been firmly established for more than 30 years as a leading supplier of wastewater treatment solutions. JIPL has established partnerships with the leading international experts within the industry to bring leading technologies from all around the world to New Zealand.

Jonassen Industrial Projects Limited (JIPL) has been firmly established for more than 30 years as a leading supplier of wastewater treatment solutions. JIPL has established partnerships with the leading international experts within the industry to bring leading technologies from all around the world to New Zealand.

It is JIPL’s mission to make overseas expertise and specialist knowledge available to all New Zealand WwTP users and specifiers.

JIPL supplies Invent solutions and technologies in New Zealand, among these the CyberFlow Flow Accelerator.

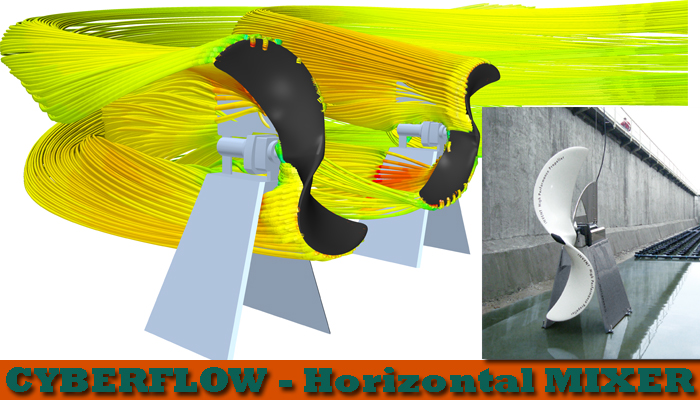

INVENT develops, produces and globally sells innovative machinery for the treatment of water and wastewater. The CyberFlow Flow Accelerator complements their product portfolio as a horizontal mixer. The INVENT CYBERFLOW® Accelerator has been specially developed and optimised for the most energy-efficient generation of horizontal flows in applications such as biological wastewater circulation in donut, racetrack, or carousel-type basins. The overall fluid mechanics concept used here is revolutionary in comparison to conventional flow generators. Extensive research and development have led to efficiency improvements of up to 30% over traditional flow generators, regardless of the application. This is made possible by a holistic, fluid mechanical optimisation approach, which considers not only the propeller design, but the interaction of the flow with the entire machine.

The most important fluid mechanical optimization is the reversal of the flow direction. The flow towards the INVENT CyberFlow Flow Accelerator, however, happens freely and without interruption and can achieve higher flow velocities at a lower energy consumption. This reclamation of energy is complemented by an adapted stand design and a specifically developed “anti-vortex“ fin on top of the power unit. A rectified flow is achieved and efficiency-reducing vortexes are avoided.

Another revolutionary approach is INVENT Power Trim Technology. This is characterized by a slightly angled drive shaft. Compared to traditionally, exactly horizontally aligned drive shafts, this allows for considerably reduced friction and energy losses on the tank’s floor and an improvement in efficiency of up to 10%. In addition an unnecessarily high flow resistance is eliminated due to the intelligent design of all components.

INVENT has installed more than 50 machines in 7 different countries around the globe in the past 2 years. See the example in the left-hand sidebar for a recent project using four Cyberflows.

Click here for more info: