Easily the most important thing I learned at IFAT – the international wastewater industry event and innovation platform packed into 230,000 square meters, the showcase of the most cutting edge technologies available worldwide – was the groundbreaking new initiative from INVENT – THINK FLUID DYNAMIX.

Easily the most important thing I learned at IFAT – the international wastewater industry event and innovation platform packed into 230,000 square meters, the showcase of the most cutting edge technologies available worldwide – was the groundbreaking new initiative from INVENT – THINK FLUID DYNAMIX.

THINK Fluid Dynamix

Do you know the fluid mechanical behaviour of your proposed or existing plant in detail?

Did you simulate your design during the planning stage?

Have you identified all possible risks to minimise projects costs?

The answer to all these questions can now be YES.

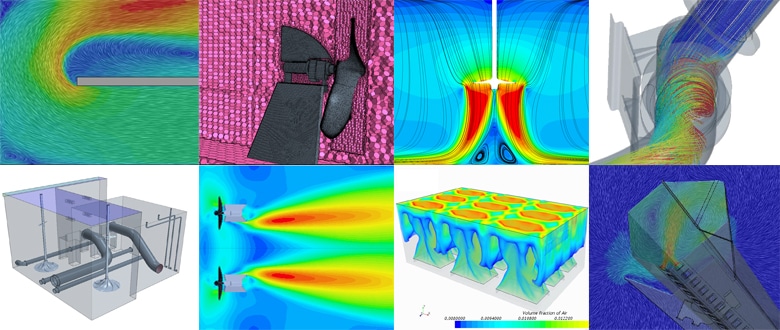

This powerful tool – Computational Fluid Dynamics – offers a whole new world of possibilities for the water and wastewater market. Today it is possible to reliably calculate all relevant process parameters in a wastewater plant even before the design stage is complete. High resolution, realistic, numerical fluid simulations in real time offer a whole new world of possibilities.

This is vitally important for councils and consultants in New Zealand to gain real insight into operational flow issues of existing industrial wastewater treatment plants and how best to deal with them. These days with rigorous water quality standards set by regulatory agencies, ensuring proper mixing and obtaining reliable measurements has become paramount for companies and utilities. We can now look at real-time changes, such as fluctuating water levels, mixing processes, changing volume flows, or the settling of particles and adjust the plant accordingly.

With new plants this can be done at the planning stage. Applied early in the system design process, THINK Fluid Dynamix analysis helps meet treatment challenges — whether these include ensuring optimum flow, reducing the costs associated with extra pumping, or pinpointing the optimum location for measurement sensors to control supervisory control and data acquisition (SCADA) systems.

Councils can now accurately model what can be expected and amend the design to avoid any costly mistakes.

So what exactly is Think Fluid Dynamix?

Computational Fluid Dynamics (CFD) is an advanced computer-based set of techniques which use numerical procedures to solve and analyze problems that involve fluid flow. It is:

- A realistic imitation of physical phenomena involving fluid flow within a computational environment

- A way to gain reliable insight into the performance and operation of a product or a plant

- A method that helps us to fully understand processes

- A method to analyze and identify issues that need attention

INVENT is the first company who has developed a toolkit for the optimisation of complex tasks in the water industry.

INVENT is the only company with the experience and technical facilities to validate and perform the essential simulations necessary to gain invaluable knowledge about your plant.

INVENT performs flow simulations with models and in large scale to provide customers with realistic operational results which help to ensure performance and reliability of plants and reduces costly design mistakes.The life cycle costs of plants can be significantly reduced if each individual component runs at its optimal operating point. These simulations ensure that the component design exactly meets the process demand. INVENT has the methods and resources to reliably execute computer based design calculations. They can simulate the process in real time and therefore show the effect of time-dependent fluctuations.

This provides valuable insight, not just into the components of a water treatment operation, but also into the system as a whole. CFD does not only help visualize flow and turbulence, but it also guides us into thinking beyond individual devices to see any given treatment problem from a system’s point of view.

Conventional CFD Modelling in the Water Industry

These significant advances in CFD modeling remove the limitations in understanding multiphase flows. Standard hydraulic calculations focus predominantly on lumped parameters, such as head loss, for a single phase, such as water. The results can significantly misrepresent the behavior of gas/water mixtures, also called multiphase flows, leading to poor mixing and inadequate mass transfer. CAD Models in general, are usually strong simplified.

Semi-empirical, traditional calculations, while useful for initial, basic estimations, do not complete the job because they do not account for realistic flows. They include broad assumptions, particularly of ideal flows and plug flow, which may not be applicable to certain processes. They don’t deliver a clear and holistic vision of the problem that is analyzed

The use of multiphase CFD models and real-world experience in mixing and mass transfer helped a company develop highly effective oxygenation and ozonation systems for retrofits or for new constructions.

Artificial Intelligence and Automatic Optimization

CFD is at the intersection of fluid mechanics, computer science, and numerical analysis. It combines engineering physics, chemistry, and math to address realistic fluid flow challenges and provides a detailed insight into what is happening in the system. Real-time simulations open up new opportunities – to help in improving your plant and products, to visualise your design in advance, to minimise risks and to lower your overall project costs.

Examples of Price Level Estimations

Contact us for price estimations. These range in price from 6,000 € – 25,000 € depending on each design case, whether these are a simple mixing analysis of reactors, multiphase simulations, or hydraulic calculations of tanks.

INVENT with its ground-breaking products is the world’s leader in the area of mixing and aeration technology for water and wastewater treatment. Careful and accurate CFD analysis can provide you and your company with the confidence and the concrete evidence that your design is optimal for the actual physical and chemical processes.

Contact us at JIPL – [email protected] to find out more about INVENT’s products and expertise and how these can contribute to your success.