In New Zealand, many treatment plants struggle with less effective processing, effluent short-circuiting and dead spots, leading to higher energy costs and variable quality of sludge. To address these challenges, JIPL offers INVENT’s advanced technology, which can help evaluate and perfect these processes.

INVENT has recognised the importance of rigorous application of fluid mechanics in wastewater treatment since the 1990s. Their in-house CFD department caters exclusively to the intricacies of water and wastewater treatment positioning INVENT at the forefront of challenging conventions and elevating industry standards.

CFD in Wastewater Treatment: Bridging Theoretical and Practical Gaps

But what is CFD? At its core, Computational Fluid Dynamics (CFD) uses applied mathematics, physics, and computational software to model and visualise fluid flows. CFD simulations are essential for optimising processes and improving efficiency in wastewater treatment.

Applications of CFD in Wastewater Treatment

- Aerated Tanks and Oxygen Transfer:

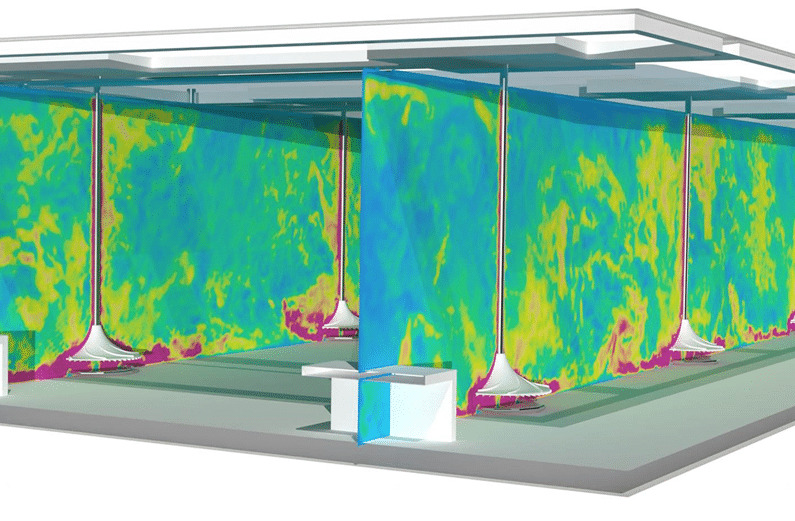

- Aerated tanks demand multiphase simulations. These simulations can predict the Standard Oxygen Transfer Rate (SOTR), a crucial metric in biological wastewater treatment. Understanding the movement and behaviour of suspended solids and activated sludge is vital. CFD helps model these phenomena, providing insights into particle trajectories, settling patterns, and more.

- Stirred Tank Reactors and Pump Stations:

- In stirred tank reactors or pump stations, surface effects marked by turbulent behaviours and vortex formation can be complex. CFD simulations model these surface effects, assisting engineers in designing and optimizing treatment processes.

- Rotating Turbomachinery:

- Precisely modelling rotating turbomachinery is crucial. In wastewater treatment plants, these machines ensure efficient flow circulation and solids suspension. Accurate modelling ensures reliable representation of real pumping operations.

- Multiphase Simulation for Aeration:

- Aeration is critical for biological oxidation processes in wastewater treatment. Understanding intricate physics, such as bubble dynamics, is essential. Factors like bubble breakup, coalescence, and mass transfer are key to reliably predicting oxygen transfer rates.

- Sludge Floc Transport:

- Sludge flocs, or aggregated particles, require careful modelling. When considering multiphase simulations for their transport, the complex factor of rheology comes into play. As the concentration of these flocs increases, the fluid’s behaviour deviates from the Newtonian ideal, adopting characteristics of non-Newtonian fluids. This alteration in fluid behaviour, coupled with flocculation effects—where particles come together to form larger aggregates—adds layers of complexity to the modelling process.

However, a significant challenge remains: the behaviour of biological compounds in wastewater cannot be explicitly modelled within fluid mechanical equations. This is where a numerical-empirical approach becomes essential. By combining theory with empirical data, we ensure accurate results rooted in real-world observations and validations.

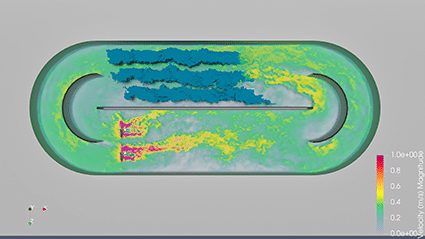

The potential applications of CFD in this arena are vast, spanning screenings, hydraulic dynamics, water distribution, and beyond. Think of anoxic tanks, clarifiers, oxidation ditches, and anaerobic digesters – CFD covers them all.

INVENT is at the forefront of CFD technology with the M-STAR software, utilizing the Lattice-Boltzmann approach for solving Navier-Stokes equations and advanced turbulence modelling techniques such as Large Eddy Simulation. Powered by GPUs, it permits time-accurate dynamic simulations, providing unparalleled insight into turbulent phenomena.

The true strength of INVENT’s CFD department lies in its superior software and hardware tools and its persistent endeavour for numerical validation. INVENT ensures the highest fidelity in CFD simulations by continually comparing simulation results with experimental data, either in collaboration with academic institutions or through onsite experiments at wastewater plants.

JIPL Offers INVENT’s Technology to New Zealand

JIPL is proud to bring INVENT’s advanced CFD technology to treatment plants across New Zealand. By implementing INVENT’s cutting-edge simulations and optimisation techniques, New Zealand’s treatment plants can achieve significant improvements in efficiency and effectiveness. This technology not only reduces energy costs but also ensures consistent, high-quality sludge production.