INVENT, available in New Zealand through JIPL, leads the wastewater market, contributing hugely to water and wastewater treatment.

INVENT specialises in mixing and aeration and the HYPERCLASSIC® Mixer is the industry standard in wastewater treatment – demonstrated by many thousands of successful applications worldwide.

Approximately 70% of the total energy demand of a water or wastewater treatment plant is consumed specifically for the mixing and aeration systems in the activated sludge process, as a result, it is becoming increasingly important to use methods that deal with resources in a responsible way.

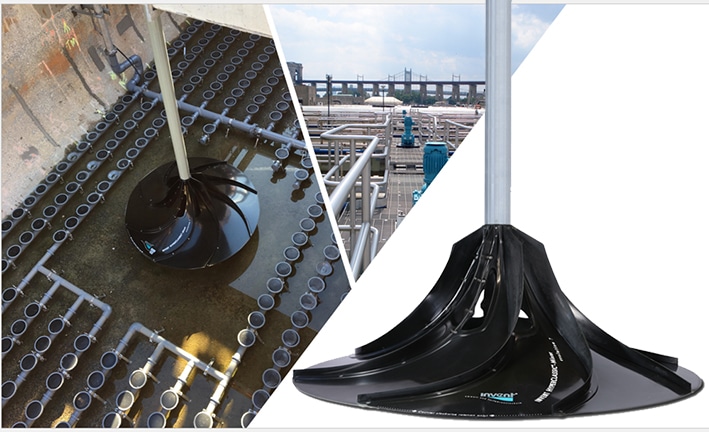

HYPERCLASSIC® -Mixer – the hyperboloid mixing technology

INVENT introduced the hyperboloid mixing technology in the early 1990s, significantly contributing to the efficiency and effectiveness of wastewater treatment plants. Since then, hyperboloid mixing technology has been continuously developed and improved.

The HYPERCLASSIC®-Mixer is the optimum mixer for all suspending and homogenization tasks required for water and wastewater treatment. The rotation of the hyperboloid-shaped mixer-body close to the bottom generates high-speed turbulence at the bottom of the basin. This reliably prevents the settling of sludge particles. Eight transport ribs generate a three-dimensional main flow with a high circulation rate, ensuring excellent, uniform mixing. Sludge flocculation is therefore subjected mechanically to minimal stress loads. Low speed at the water surface consistently prevents aerosol formation and oxygen transfer. The efficient design and the use of long-lasting, quality materials minimize operating and maintenance costs.

Example New York City

The tremendous potential for energy savings can be seen in the large wastewater treatment plant Bowery Bay in New York City.

At an equal purifying capacity, the energy costs of the Hyperboloid-Mixers are only a third of the original mixers they have replaced. Reduced operational costs compensate for the slightly higher initial capital costs. In total, the savings have mounted up to 3,500,000 US Dollars over a period of 10 years. The New York example demonstrates that the selection of mixing equipment significantly affects the operating costs of large wastewater treatment plants.

Due to the significant energy savings and high level of reliability of the INVENT equipment the City of New York have also converted Wards Island, Jamaica Bay, Coney Island, Rockaway Beach and Hunts Point plants to INVENT Mixers.