Water is a precious resource that sustains all life, but its contamination continues to be a growing worldwide concern. Among the many industries that generate wastewater, the pulp and paper industry faces unique challenges due to the nature of its production processes. To address these challenges and ensure efficient wastewater treatment, INVENT offers the HYPERCLASSIC®-Mixing and Aeration System—a revolutionary solution that tackles the demanding tasks of aerobic wastewater treatment seamlessly.

Paper, an integral part of our lives, is widely used in various forms daily. To meet the enormous demand for paper products, the pulp and paper industry relies on a consistent supply of raw materials—wood and water. As the industry strives to optimize manufacturing processes and reduce water consumption, efficient wastewater treatment becomes paramount.

Challenges in Aerobic Wastewater Treatment:

The wastewater generated in the pulp and paper industry contains a high input of limescale, fillers, and binding agents, along with significant amounts of organic compounds. Aerobic wastewater treatment, involving oxygen transfer to bacteria, effectively degrades organic pollutants. However, in the case of paper mill wastewater, this step is complicated by several operational boundary conditions.

One such challenge arises from the presence of hard water, which causes lime precipitation and sedimentation throughout the basin. The accumulation of sediments and lime particles hampers the aeration system’s efficiency and can lead to clogging and reduced performance. Additionally, high temperatures and deep aeration depths further compound the difficulties in maintaining an effective aerobic process. These challenges can interrupt the oxygen supply and impact the overall treatment efficiency, leading to non-compliance with approved target values.

INVENT HYPERCLASSIC® – Mixing and Aeration System:

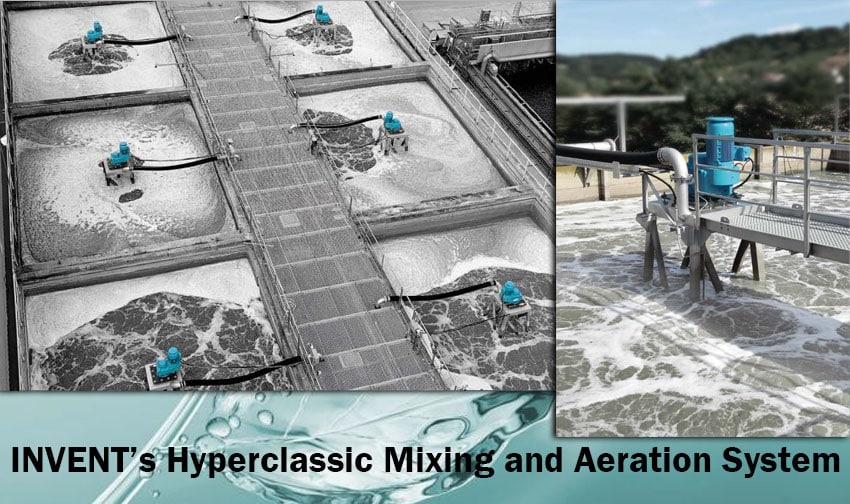

The HYPERCLASSIC®-Mixing and Aeration System from INVENT offers an ingenious solution that combines the characteristics of an agitator and an aerator. This unique system allows for flexible operating and application ranges, including agitation without aeration, fine bubble aeration with homogeneous mixing, and intermittent operation.

The system’s design and construction, along with its mechanical aeration principle, provide several advantages:

- High oxygen supply capacity, even in difficult media with high total solids and surface-active substances.

- No increased pressure drop during operation, unlike membrane aeration systems.

- Prevention of deposits in all operating stages, thanks to effective mixing.

- Tailored materials to withstand varying operating conditions like temperature, pH value, salinity, and precipitation.

The HYPERCLASSIC ® -Mixing and Aeration System can be delivered in a stainless steel cage, making it easy to lift out when needed without having to empty the aeration tank. Because of its weight, it is safely positioned at the installation site.

The Perfect Solution for Any Pulp and Paper Mill

Efficient wastewater treatment is vital for the sustainable and responsible operation of the pulp and paper industry. INVENT’s HYPERCLASSIC®-Mixing and Aeration System, offers a reliable, low-maintenance, and energy-efficient solution for tackling the demanding challenges of aerobic wastewater treatment in this industry. By choosing INVENT’s innovative products, paper and pulp manufacturers can contribute to the preservation of water quality on a global scale, demonstrating their commitment to environmental responsibility and sustainable practices.