JIPL is shaping the engineering landscape of New Zealand with our process engineering and design skills.

JIPL provides specifically designed equipment and complete systems that include paint lines, pre-treatment plants, industrial ovens, overhead conveyors, metal treatment plants, effluent treatment plants, and mechanical handling systems. JIPL’s expertise in designing and building long-lasting quality equipment ensures maximum production efficiency with minimum energy and maintenance costs.

Process Engineering

JIPL’s process specialist analyses, designs, and optimises processes to improve operational efficiency, product quality and safety while minimising costs. By analysing a company’s current processes and identifying opportunities for improvement we ensure the best outcomes and minimise operating costs. As a result, we design our cooling plants to maximize production efficiency and minimize space requirements. JIPL prides itself on understanding and answering its customers’ needs and embracing innovation and development.

At JIPL we work hard to understand your processes and pain points so that we can provide customized process solutions to suit every individual requirement. We provide complete systems design – ovens, overhead conveyors, metal treatment plants, associated effluent treatment plants (solid, liquid, and VOCs), and mechanical handling systems.

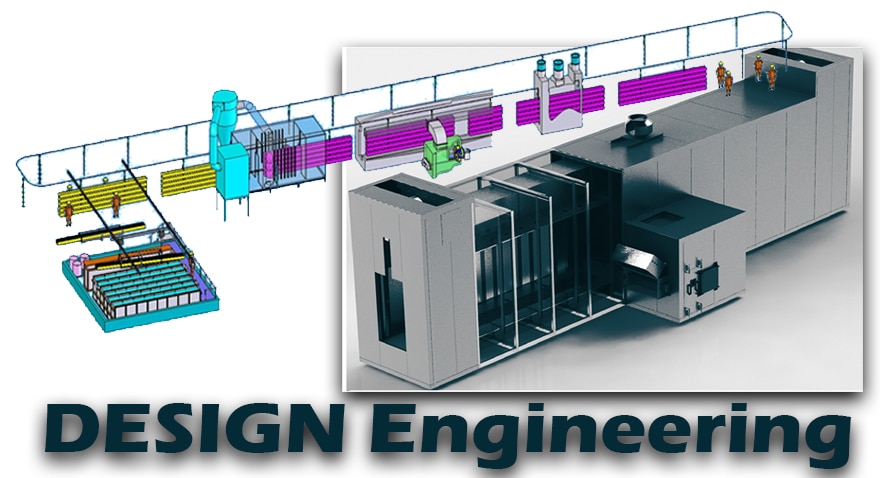

Design Engineering

The JIPL design team transforms ideas into reality with its broad and established design engineering expertise. The team has the depth of experience, diverse range of skills, and interpretive abilities to translate customer ideas into reality. JIPL provides complete design packages, plant layouts, detailed design drawings, manufacturing drawings, and process animations, using sophisticated 3D software.

JIPL’s in-house design specialists analyze needs, constraints, and options, generate concept designs and ideas, research and test options and alternatives, support calculations and logic descriptions, and optimize plant layouts and space utilization. JIPL also has the capability to visualize and present the optimum solution, including 3D solid modelling, detailed design specifications and drawings, individual component manufacturing drawings, fully expanded bills of materials and process, and product animations.

JIPL’s “design for manufacturing” expertise and access to methods and techniques drawn from our experience across a wide range of industries and processes provide added advantages for our clients.

A recent project undertaken by JIPL is the design and build to increase the manufacturing requirements for a sports apparel manufacturer. JIPL’s process specialist redesigned the old batch process into a flow process. To best suit this process JIPL decided to use MiniTec for the framework for the conveyor and the load/unload mechanism. Here JIPL’s solution for OBO trebled the plant’s capacity and is achieving consistent quality throughout the plant solving a key business issue and increasing production throughput.

JIPL’s in-house design capability, cutting-edge technology, and “design for manufacturing” expertise provide customers with the best possible solutions. JIPL’s flexible approach and commitment to innovation and development make us an ideal partner for your industrial design and engineering needs.