Many manufacturers experience problems with their industrial ovens and process heating….uneven heating, airflow and dust problems are common. Often, engineering staff will attempt to provide a stop-gap solution which in many cases causes additional problems and does not usually remedy the original challenge.

Efficient heating and cooling requires a full understanding of heat transfer technology

Detailed and complex calculations are required to ensure that specific objects can be heated or cooled to suit the product at the required production rate. From this data, the plant can be designed to produce exact and repeatable results.

JIPL has years of experience in air transfer systems, both heating and cooling and were the first to bring this innovative technology to NZ.

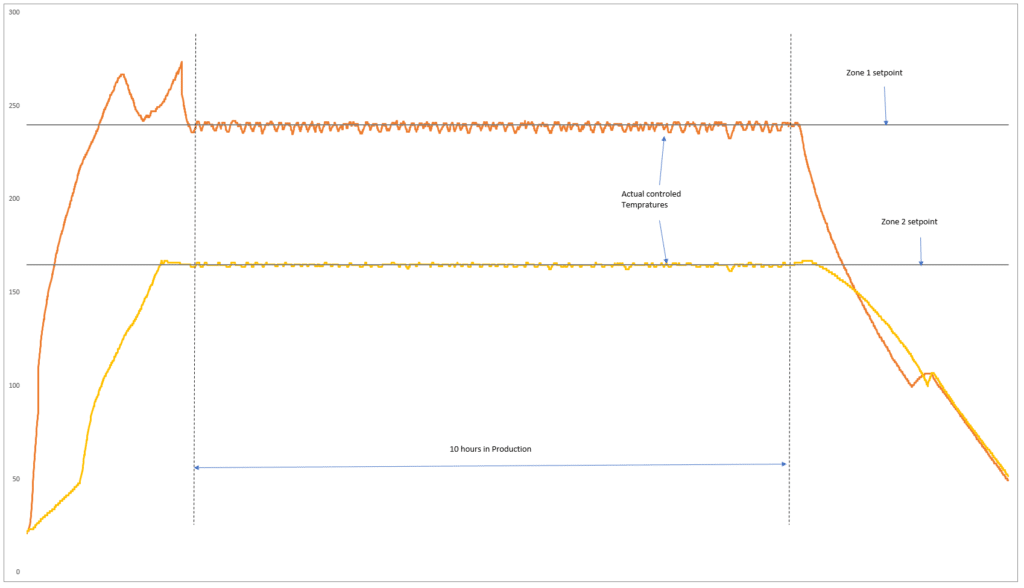

JIPL has recently completed a project for an iconic NZ client where JIPL redeveloped their process from Batch manufacture to a flow process. The project included full design, build, installation, and commissioning of the process. This included an oven with two separate production lines, each with two temperature zones (preheat for up to 6 minutes & Soak for 5 minutes). In addition, a cooling section for each line was included to rapidly cool the molds and it was all connected using power and free conveyors. JIPL worked collaboratively with the client to meet tight process constraints and satisfy the necessary budget limitations.

At JIPL, we design our ovens to provide for long, low-maintenance life. High reliability and minimal energy consumption in operation are our key focus. Our oven is designed using precision sheet metal components that bolt and rivet together ensuring minimum heat transfer through the oven fabric.

Airflow (volume and velocity) is critical for the effective and efficient curing of their products. The oven airflow will raise the product temperature within 6 minutes and will hold at temperature (180oC) for 25 minutes. An integral cooling system is included to reduce product temperatures to below 60c within 6 minutes.

JIPL’s oven technology is very efficient and effective and will remain so for a minimum of 20 years – We value and prioritise our long-term value to your business rather than purely cost alone.

At JIPL we work hard to understand your processes and pain points so that we can provide customized process solutions to suit every individual requirement. We provide complete systems design – ovens, overhead conveyors, metal treatment plants, associated effluent treatment plants (solid, liquid, and VOCs), and mechanical handling systems.