JIPL/FL has the technology of the future set to revolutionise the New Zealand meat industry. JIPL /FL with AMS Filtration is offering the New Zealand market the groundbreaking world-only Ti membrane technology.

Red meat processing facilities generate large volumes of wastewater rich in organic contaminants and nutrients. While expensive, the removal of these contaminants is necessary in order to comply with water discharge regulations. Red meat processing facilities are strong candidates for advanced treatment processes aimed at removal and/or subsequent recovery of valuable resources.

JIPL/FL’s new 100% pure metal membrane filtration technology works well in these challenging conditions outperforming traditional methods. The membranes work by providing precise filtration that can isolate desired components from a liquid/slurry.

Metal membrane microfiltration & ultrafiltration (MF & UF) offers solutions for valuable protein recovery and membrane distillation. The Ti metal membrane consistently provides high levels of removal in all tests conducted in this work without chemicals.

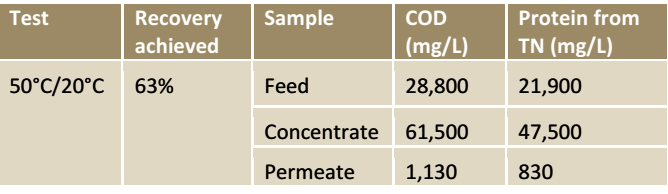

JIPL / FL have run a number of tests and pilot studies at several meat rendering plants. View the staggering results below:

The use of Metal Membrane Filtration on a real abattoir’s combined effluent as well as a stick water stream consistently showed near complete removal of fats (99%) and very high COD removal (>86%).

The capacity of the MF membrane to remove all observable particulate matter, leaving primarily soluble components, increases the opportunities for the discharged permeate to be recycled as is (e.g. cooling water), also the dramatically improved recovery of fats and proteins offers a number of options for by-product generation. The dried solids produced by the membrane technology had a protein concentration of 75 wt%. This solid could possibly be used to enhance the protein content of meat meal among other options.

Membrane clean in place (CIP) trials were effective at restoring fluxes in the metal membrane. Use of CIP on a daily basis would not lead to significant chemical costs, nor significantly add volume or salt loads to the combined effluent.

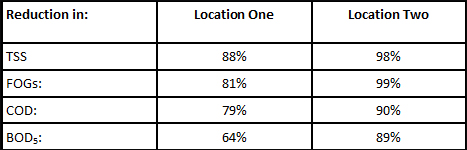

The pilot test results at two New Zealand meat rendering plants are incredibly impressive, where E coli is seen to be practically eliminated:

AMS Filtration membranes and systems are remarkable. The AMS DuraSter© range of metallic microfiltration membranes offer a new level of performance, corrosion resistance, and durability in crossflow membrane micro-filtration. They are 100% titanium which overcomes the limitations of past filtration methods and delivers superior performance. These metal membranes allow much easier cleaning in place (CIP) and additional sanitation steps, (without or much limited the use of chemicals). There are no limitations around pressure, flow, pH, and temperature. They are non-corrosive and of course, high solids application is a matter of fact.

With this technology JIPL/FL can now offer water reuse, reduce power and chemical use. We can guarantee quality and eliminate redundant technologies. We are seeing less product waste, recourses reused, and a huge reduction in trade waste dollars.