The first JIPL supplied, digester gas mixing system in Australasia has been installed in the new digester at the Taupo Wastewater Treatment plant. The technology is provided through Monsal UK Ltd – whose track record includes over 200 digester mixing applications, successfully carried out over the last 11 years.

The first JIPL supplied, digester gas mixing system in Australasia has been installed in the new digester at the Taupo Wastewater Treatment plant. The technology is provided through Monsal UK Ltd – whose track record includes over 200 digester mixing applications, successfully carried out over the last 11 years.

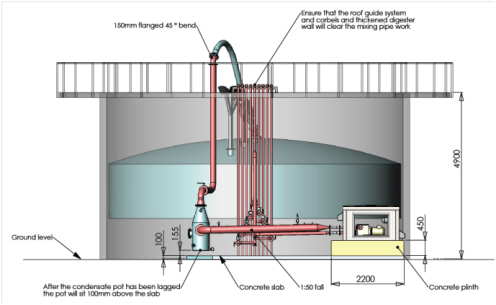

The Monsal (UK) sequential gas mixing system is based on the collection and recirculation of biogas from the digester headspace through a duty gas compressor. Compressed biogas is delivered to a gas mixing manifold from which a number of gas mixing lines are introduced to the digester. The bio-gas mixing system is designed to achieve:

- The required process mixing output at the lowest electrical installed power

- Thorough mixing within 2 hours, even with thick sludge (> 8%)

- Low maintenance and ease of operation

- Simple integration into any existing or new digester.

The Monsal technologies available through JIPL include:

- Advanced Digestion – Enhanced Enzymic Hydrolysis: Anaerobic Digestion

- Sequential Gas (and Air) Mixing Systems

- Sludge Heat Exchangers – heating and cooling

- Bio-waste Anaerobic Digestion Technologies (green and food wastes

JIPL works closely with Monsal, to provide their specialist technologies throughout Australasia.

Monsal are the largest UK-based specialist digester team and are the only UK digestion company to maintain the very high standards of ISO 9001, 14001 and 18001 with consistently high UVDB Verify scores. This provides JIPL and our customers with proven technology, excellent performance, and very high standards.