Here’s Everything you Need to Know about Drinking Water Standards

Water is vital for life – every human on this planet needs water to survive. Over and over again we hear about the benefits of drinking water. However our planet might be blue, but we may still be left thirsty. While almost three-quarters of the Earth’s surface is covered in water, less than 3 percent of that resource is actually freshwater, of which maybe only 1 percent is readily accessible. We depend on that 1 percent.

Have you ever wondered about the quality and purity of the water you are drinking every day?

Sources of Water and its Way to the Tap

- Groundwater – Groundwater, aquifer, spring / Well / Purification / Tap

- Surface water – Glaciers, rivers, lakes, wetlands / Purification / Tap

- Sea water – Pretreatment / Desalination / Purification / Tap

The regulations for drinking water quality vary worldwide. In New Zealand during 2014/15, bacterial compliance was achieved for 96.8 percent of the population and chemical compliance for 98.7 percent of the population. Achievement against the protozoal Standards remains around 80 percent.

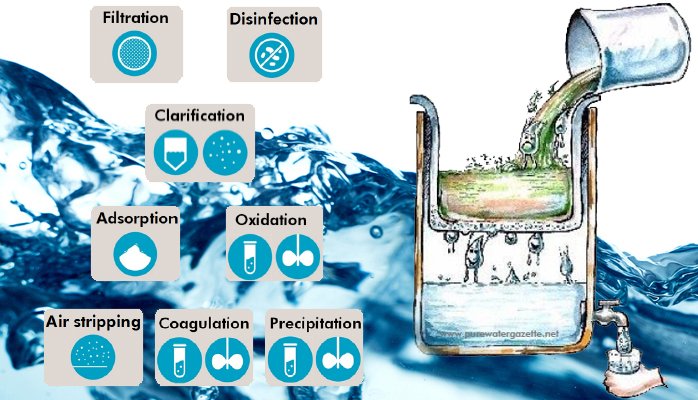

Water Purification Treatment Process

Water purification is an essential treatment to provide clean and healthy drinking water all over the world. INVENT offers the optimum solution for Mixing applications in Water treatment plants with the CYBERPITCH®and HYPERCLASSIC® Mixer. INVENT’s aim is to be is to be the world leader in mixing and aeration.

Mixing steps in WwTPs

- Mixing is needed to remove:

– Dissolved solids

– Suspended solids and colloids, which do not settle sufficiently - Mixing goal: Grow particle flocs, separable by sedimentation, flotation, and/ or filters

- The mixed treatment steps are:

– 1st step: Coagulation/Precipitation

– 2nd step: Flocculation

-

FLASH MIXING IN WATER TREATMENT

1st step: Coagulation / Precipitation

- Precipitation: Removal of dissolved solids by adding precipitating agents to the water flow and initiate a phase transition. The precipitated solids are separated alongside the other suspended solids

- Colloidal Particles (0,001-1 μm) are stable in suspension due to repelling negative surface charges

- Neutralization at the boundary layer around the particle surfaces is provided through dosing of coagulants. This is the basis for microfloc formation

Main Mixing Goals for Flash Mixing:

- Complete mixing of water and dosed chemicals at high turbulence for reaction and destabilization

- High rate of colloid contacts for destabilization and aggregation of the neutralized particle suspension

- High mixing intensity is needed

Solution: Flash Mixing with CYBERPITCH® Mixer

- Drive unit SEW, Siemens

- Mounting base Carbon steel coated

- Shaft Stainless steel

- Mixer body Stainless steel

- Fixing material Stainless steel 304/316

2. GENTLE MIXING IN WATER TREATMENT

2nd step: Flocculation

- Flocculating agents do enhance agglomeration by forming molecular bridges between particles, based on their big molecular structure and/or ionic charge

- Gentle particle collisions result in growth of the micro flocs to settleable macro flocs

2nd step: Mixing in Flocculation

- Flocculating agent dosing (cationic, anionic or non-ionic

polymers) - Inflow of destabilized suspension with microflocs > 1μm

- Usually HRT of several minutes (10- 30 min)

Main Mixing Goals for Gentle Mixing:

- Provide particle interaction (collision) for floc growth

- Avoid floc damage by mixing

- No deposits in the mixed chambersMixing in Flocculation – Makes the difference!

- Mixing influences the desired floc formation significantly

- Flocculation has – a direct influence on the performance of the complete clarification process

– a layout optimum for each type of solid / liquid separation downstream (Sedimentation / Flotation / Filtration) - Influence flocculation performance by choosing:

– the flocculation design (e.g. technical layout, tapering)

– the flocculator typeSolution: Gentle Mixing with the HYPERCLASSIC® Mixer

- Drive unit SEW, Siemens

- Mounting base Carbon steel coated

- Shaft FRP (standard) or Stainless steel

- Mixer body FRP or high strength impact resistant plastics

- Fixing material Stainless steel

Water Needs Responsibility

The future calls for fresh thinking and new innovations. In New Zealand, JIPL is INVENT’s supplier. INVENT specialises in products that enhance the environment, and that can be seamlessly integrated into unique sustainable system solutions.